Dip-Tech

DX3 — The future is NOW!

DipTech defines digital priniting with ceramic colors NEW!

- up to 12 Ink channels for highest flexibility in production

- high resolution up to 5760 dpi apparent resolution

- NEW FEATURES

- GLASS SCANNER

- Scans the borders of the glass and crops the image according to the actual glass size. The user-friendly software enables the operator to control the positioning of the trimmed image.

- MULTI-TASKING GLASS HANDLING SYSTEM

- The printer’s split conveyor system allows the machine to print and unload at the same time (DX3 to 6 m only).

- AUTOMATIC LOAD SYSTEM

- Shifts the glass forward from the set-up area, enabling continuous printing while new glass is being loaded (DX3 to 4 m only).

- METALLIC INK SOLUTION

- A dedicated system for handling precious metal inks that prevents ink contamination and minimizes ink waste.

- INDUSTRY 4.0 COMPLIANCE FOR SMART MANUFACTURING

- Dip Tech’s NExT operating system sends production data to the factory control software.

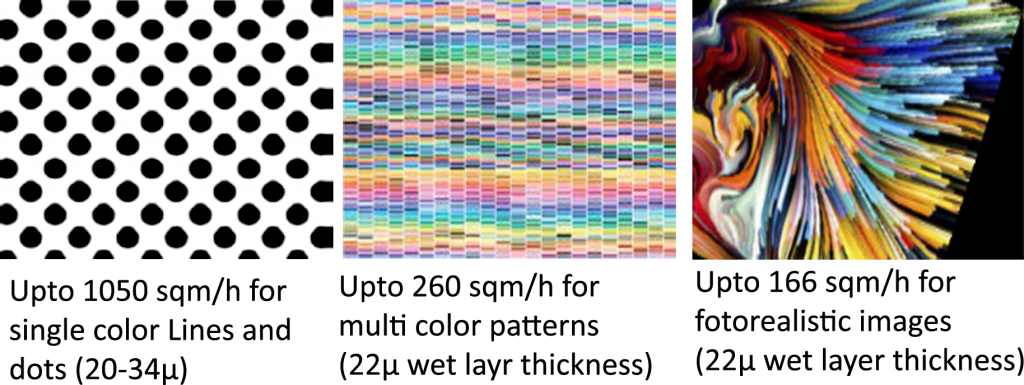

Digital printing technology opens new business opportunities to glass processors and enables to eliminate the extra cost involved in the use of traditional screen-printing. Main advantages of digital printing:

- opens up new business opportunities through new glass product’s offering

- eliminates screens and related cost like screen cleaning and storage

- enables simultaneous multi-color printing

- enables high resolution image printing

- less labor intensive

- enables variable information

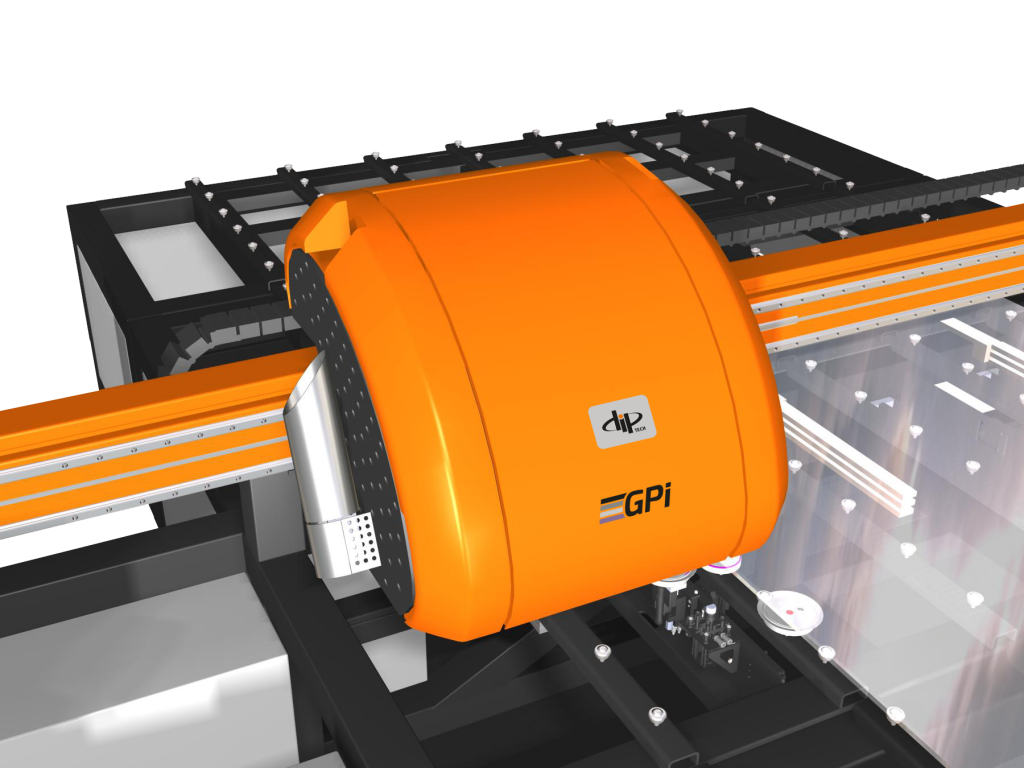

The NEra-D; Nera-V and GPi series are digital printers and using solvent-based ceramic ink.

Graphic patterns designed in digital format and processed with RIP software are converted to printing models and jetted through Drop-On-Demand printing technology onto flat glass surfaces.