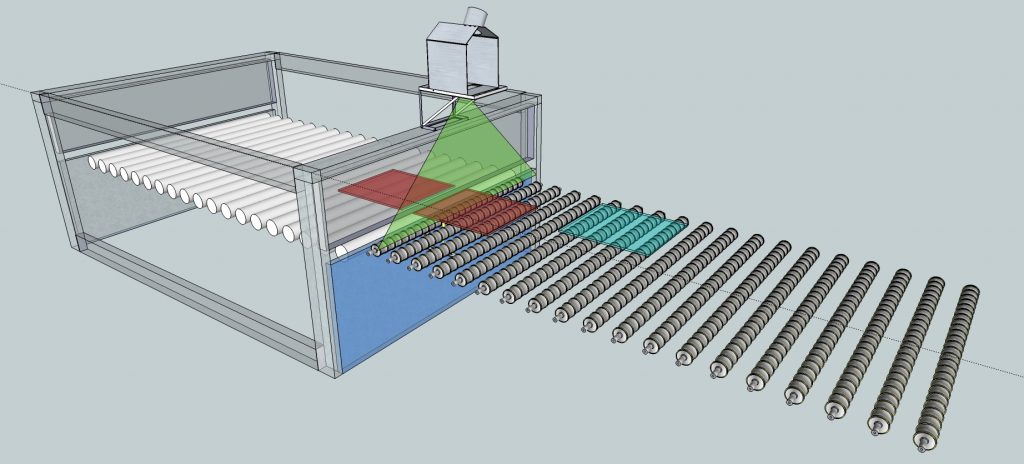

Temperature scanner for ESG systems

MP150 Linescanner

- scanning speed 150 lines per second

- upto 1024 mesuring points per line

- optical resolution upto 200:1

- integrated laser for adjustment

- integrated TCP/IP Ethernet interface upto 100 Mbit/s

Product description

The GS150 System is an automated temperature measurement system for glass bending, forming, annealing, and tempering processes.

Core of the system is the MP150 linescanner. The MP150 measures a line of up to 1024 points using a rotating mirror that scans a 90° field-of-view up to 150 times per second. The high scan rate allows rapid detection of temperature non-uniformities and hot spots. The scanning of a glass part is initiated by the measured temperature, or an external “trigger” signal. As each heated glass part traverses the field-of-view, a two-dimensional thermal image or “thermogram” is formed.

The system software provides features to sub-divide thermal images from MP150 into portions of specific interest, the zones. The zone grid overlaid on the thermal image represents the heating elements in the furnace. Temperatures in each zone can be processed for a certain math function like average, maximum, or minimum temperatures. In case of a thermal defect, the software triggers an alarm. For later analysis, the thermal image is automatically stored in a separate file. The alarm can also be output with an optional digital output module.